Click here to join Express Pune WhatsApp channel and get a curated list of our stories

From construction blocks to murals to sculptures: The afterlife of Ganpati idols

Kumbhar is among the murtikars or makers of idols, who have taken up the challenge of working with recycled shaadu maati, natural clay that is an eco-friendly alternative to plaster of Paris as a raw material for making idols.

In 2022, the campaign collected 23 tonnes of clay while in 2025, the amount rose to 49.5 tonnes. Since 2024, the PMC has been collaborating with Punaravartan.

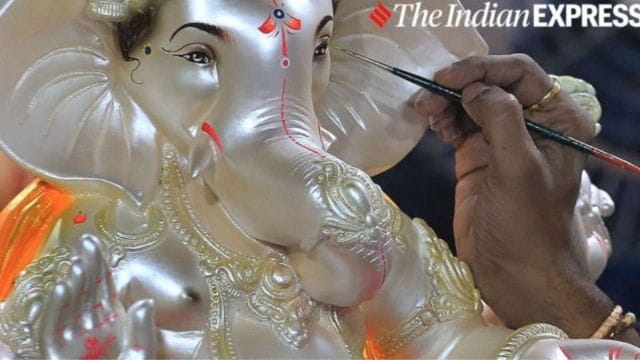

In 2022, the campaign collected 23 tonnes of clay while in 2025, the amount rose to 49.5 tonnes. Since 2024, the PMC has been collaborating with Punaravartan.Deepak Vasant Kumbhar, an artisan who creates some of the finest Ganesh idols in the city, looks at the overcast sky that pelts rain and wishes for sunshine. Kumbhar has received five tonnes of clay and is eager to get started on sculpting idols. “The clay is wet; it needs to be left out in the sun to dry,” he says. The clay will be cleaned of the remains of past idols – flowers or bits of ornaments – before Kumbhar shapes it into a new generation of Ganpatis.

Kumbhar is among the murtikars or makers of idols, who have taken up the challenge of working with recycled shaadu maati, natural clay that is an eco-friendly alternative to plaster of Paris as a raw material for making idols. Shaadu maati is mined from Guajarat and is a non-renewable natural resource, making recycling it a better option to immersing it in water bodies.

Kumbhar makes almost 10,000 idols annually, and needs around 20 tonnes of shaadu maati. “We have to get the clay from Gujarat or Mumbai. It is expensive as there are transportation costs involved. Using recycled clay helps save on costs,” he says. Kumbhar has found that mixing new clay with the recycled one gives the idols more strength and a good finish. “Last year, I received six to seven tonnes of clay. This year, it is five tonnes,” he says.

After the celebration of Ganeshotsav, the main annual festival of Maharashtra, winds down and visarjan processions go back home, the real work begins for environment-loving people across the city. Individuals, representatives of educational institutions, workers of Non Governmental Organisations and staff from the Pune Municipal Corporation (PMC) and the Pimpri Chinchwad Municipal Corporation (PCMC) began the task of collecting the clay that is used in the making of idols.

“This is a very challenging process. A lot of labour goes into it, because the clay is very heavy when wet and transporting it is very difficult,” says Manisha Sheth, Founder and Campaign Director of the Punaravartan campaign that has been working towards generating awareness and collecting and reusing shaadu maati after the immersion of idols.

The Punaravartan campaign aims to protect natural water bodies from being clogged by large quantities of clay during immersion, and conserve the clay itself. “We put the clay back into the supply chain, thus establishing a circular economy,” says Sheth. The campaign was initiated by the eCoexist Foundation in 2020 and is in its sixth consecutive year. Over the years, a new tradition has been built, where idols are not immersed in water bodies but in immersion tanks set up across the city. Though ritual immersions in rivers and other natural water bodies have not stopped, there has been an increase in the number of idols that find their way into tanks instead. In 2022, the campaign collected 23 tonnes of clay while in 2025, the amount rose to 49.5 tonnes. Since 2024, the PMC has been collaborating with Punaravartan.

“This year, the residents and municipal corporations of Pune and Pimpri Chinchwad together have collected over 60 tons of clay. The PMC and the PCMC set up separate immersion tanks at 46 locations in Pune and 26 locations in Pimpri Chinchwad to invite people to immerse their clay idols in these tanks. After the fifth, seventh and tenth day of Ganeshotsav, these tanks were emptied out to collect the clay at the bottom of the tanks and stored in sacks,” says Sheth.

She adds that members of the Poornam Ecovision Foundation went door to door to pick up clay from people’s homes for a small fee. “Finally, on September 14, volunteers from the Paryavaran Gatividhi group and others set up temporary collection centers at 61 locations in Pune and 25 locations in Pimpri Chinchwad and invited citizens to come and drop their home immersion clay here,” says Sheth.

Feats of clay

The clay collected through door-to-door and home immersion methods is the cleanest. These are handed to artisans directly as they can immediately reuse it. The quality of public immersion clay is mixed, as PoP idols also tend to be immersed with shaadu maati idols ones. This clay is given to architects working with green building technologies. Anybody, who wishes to become a part of the recycling effort, can pick up the clay for reuse, free of charge. “The only condition is that the learnings and experiments be shared openly in the public domain for collective benefit,” says Sheth.

At present, organisations across the city are experimenting with the recycled clay to make construction blocks, wall plasters, pond lining sealant and murals. Dhruvang Hingmire, an architect who creates eco-friendly homes using cement-free traditional methods and material, has experimented with the recycled shaadu maati by adding sand and binders, such as lime, to stabilize it. “If you use it the way it is for building, it can either erode over time with exposure to water or develop cracks,” he says.

“We carried out a few tests to understand the material and found out that it is 25 to 30 per cent expansive. This means that the material can shrink in the volume by 30 per cent after it dries. Again, more stabilization is required when we are using it,” he says. The architect and his students at Hunnar Gurukul have found that drying the clay before powdering it is time-consuming.

“It is much easier to mix the clay in water, let it dissolve and, then, strain the water itself to get the clean clay,” he says. They have created a wall as an experiment, and plan a larger one. “If this experiment works and we can use the clay in construction, we will be saving on sand and cement, which have extremely high economic and ecological cost,” he says.

Click here to join Express Pune WhatsApp channel and get a curated list of our stories