From The Lab: Helping a scratched surface heal itself

The self-cleaning coatings have been developed using water material like rice husk and fly ash from power stations.

If the contact angle of water molecules and the surface is greater than 150 degrees, water does not stick to the surface.

If the contact angle of water molecules and the surface is greater than 150 degrees, water does not stick to the surface.The research: Developing ‘hydro-phobic’ or water-repelling polymers/pigments that can be used as coating on a surface, and thus prevent corrosion.

By: Dr S Syed Azim

Head, Corrosion and Materials Protection division, Central Electrochemical Research Institute, Karaikudi, Tamil Nadu

Our team has been working for several years on anti-corrosion technologies. We have developed techniques and methods to prevent and minimise corrosion of materials commonly used in bridges, thermal power stations, nuclear power stations, etc. The current research is focused on development of smart or ‘intelligent’ coatings to prevent corrosion. Traditional coatings are designed to passively protect the substrate to which they are applied by providing a barrier between the surface and the environment. Smart coatings should be able to sense a change in conditions in the environment and respond to that change in a predictable and noticeable manner.

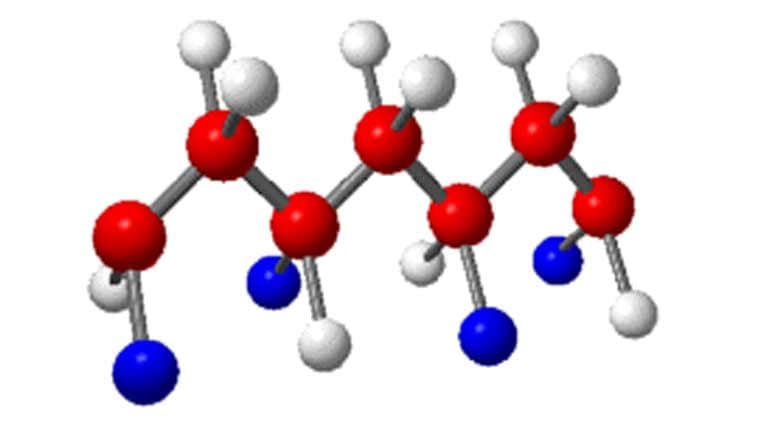

Moisture is the main reason why corrosion takes place. Preventing corrosion, therefore, is all about minimising the contact between water and the surface. If the contact angle of water molecules and the surface is greater than 150 degrees, water does not stick to the surface. It rolls down, even if the surface is flat. We are in the process of developing such hydro-phobic or water-repelling polymers/ pigments that do not allow water to stick to them. We have succeeded in ensuring that the contact angle of water with the polymer/pigment is more than 155 degree. This polymer/pigment can be used as an excellent coating.

[related-post]

Coating does not necessarily mean coloured paints. It can be clear coating as well. It can be applied to the wind shield of a car, for example. Because the water does not stick on to it, and rolls down, it also cleans up the dirt on the surface. The coating can be incorporated into a paint formulation as well to work as anti-corrosion/self -cleaning paints.

The self-cleaning coatings have been developed using water material like rice husk and fly ash from power stations. Both are a source of silica, which we convert into nano-silica — an effective hydro-phobic material.

Using these coatings, the life of the material can be increased by at least two times.

We have also developed ‘self-healing’ abilities of a coating. When we get small cuts on our bodies, the body heals automatically. Similarly, organic paints can be modified with the addition of certain molecules such as conducting polymers, inhibitor loaded micro capsules etc, which can help in ‘self-healing’ minor damages or scratches. The paint responds to external stimuli and acts to treat its ‘wounds’ and prevent further damage.

It’s from mechanical damage or scratches that corrosion starts. We have mixed certain molecules in the coating that detect such scratches and open up the coating around them in order to bridge the gap.

‘Self-healing’ happens in a small area, typically 100 to 150 sq cm of damage. If the scratch is bigger, then self-healing does not work. But because the coating can sense the damage itself, it kicks itself into action the moment a small crack or scratch is developed, preventing it from growing bigger.

We have demonstrated the technology at the laboratory scale. We are now in the process of finalising a pilot project to assess its effectiveness on an industrial scale.

Azim can be reached at azimcecri@gmail.com