Rock Solid

Deep below the Rohtang Pass,a tunnel to link Lahaul-Spiti and strategic parts of Ladakh is in the making. A day at work at an altitude of 10,360 feet.

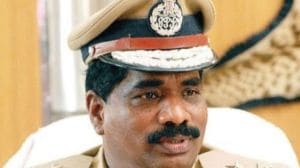

Bhagwan Das Jangade

Executive Engineer,

Rohtang Tunnel Project

AGE: 40

ROUTINE: Deep below the Rohtang Pass,work is on 24215;7,and as officer commanding,Bhagwan Das Jangade does not stick to any specific schedule or shift. He is always on the job. His day begins early and he monitors every part of the 8.8-km tunnel. Jangade spends close to seven hours inside the tunnel,and the rest of the time in his small cubicle on the site,a few metres outside the tunnel. He calls it a day only by 7 in the evening,once his second-in-command,A N Murty,is ready to take over.

Yoga has always been a part of Bhagwan Das Jangades early morning routine. But for the last one year,Jangade has combined that with some deep breathing exercises and relaxation asanas in the evenings too. Its the only way to get the lungs and body free of all the dust in the tunnel, says Jangade.

The 40-year-old works for the Border Roads Organisation BRO as an executive engineer on the Rohtang Tunnel Project,a technologically challenging assignment that aims to build an all-weather link from Lahaul-Spiti Valley in Himachal Pradesh to strategic areas of Ladakh. The first kilometre of the 8.8-km tunnel is ready and Jangade says they are on schedule to meet the target date of February 15,2015 for the entire tunnel.

Work is on simultaneously from the south portal end on the Manali side and the north portal end towards Keylong. According to Chief Engineer P K Mahajan,there are close to 500 labourers and experts from Germany and Austria working on the tunnel. With the tunnel located at an altitude of 10,360 feet,a 91-kilowatt ventilation pump from Austria helps circulate air inside the tunnel.

The tunnel,once ready,will change the face of Lahaul Valley,where more than 40,000 people remain cut off from the rest of the country for almost seven months due to heavy snowfall at Rohtang Pass. The 8.8-km-long tunnel will reduce the distance between Manali and Keylong by 46 km and travel time by two-and-a half hoursat present,it takes about five hours. The single-tube,double-lane tunnel is being designed for a traffic density of 3,000 vehicles a day,moving at 80 kmph.

But right now,this is a tunnel in the making. Dust,darkness,the deafening sounds of machines,a constant sound of water dripping,slush from mica rocksjust an hour in the tunnel makes your head heavy,your eyes tired and searching for light and lungs asking for fresh air. The walk inside is slow as you wade through the slush. Sometimes,the dust drops visibility to 20 metres. Oxygen levels are low and in winters,temperatures plummet down to as low as minus ten degrees centigrade.

But this is Jangades workstation and these are the conditions that bring out the best in him.

Every morning,he reaches the BROs administrative office in Solang,12 km from the project site and 25 km from Manali. Here,he meets his boss Mahajan,reports to him about the previous days progress and then heads towards the tunnel site at about 7.30 a.m.

After a quick halt at his office cabin just outside the tunnel,Jangade prepares to enter the tunnel. He dons a safety reflective jacket,gum boots,a helmet,ear plugs and a mask to cover his nose and mouth. At the entrance of the tunnel,he stops to collect his tally number from a counter,which keeps track of the number of people inside the tunnel at any given hour,with as many as 500 workers working 24 hours on an 11-hour shift daily.

As he enters,Jangade looks around the tunnela quick look at the face of the tunnel to see if everythings fine,he saysand has a word with the foreman. Jangade then monitors the excavation progress,which is in its second stagespreading the concrete through a highly-specialised spray pump,fixing rock bolts inside the wall and the drilling process with a two-arm boomer which breaks the rocks slowly.

Jangade looks intently,taking constant updates from the staff. Its a highly computerised drill, says Jangade,explaining the technical details. The drilling creates holes and then an explosive is filled inside the holes. Jangade monitors the process of filling,charging and later blasting,which is done thrice a day. Through all this,he sips orange juice and water to keep the body hydrated and munches on jaggery,as it helps melt the dust and aids in flushing it out from the internal organs.

I check the scaling,removal of muck and then the profile of the tunnel with the geologist,as we check thoroughly for loose rocks,change of strata in the nine types of rocks inside,any chances of hot sulphur water coming in the tunnel, says Jangade,raising his voice through the shrill sound of drilling.

Jangade has braved many loose rocks,but says ensuring world-class safety standards is one of the most vital parts of his daily routine. He stops to tell us to secure our helmets.

He also checks for the holes drilled and the quantity of explosives used. An over-cut means we have gone beyond the dimensions. We dont want that because that means cost overruns, he says.

The process continues all day,with Jangade getting out of the tunnel for a quick lunch break at 1 p.m. and conducting short meetings to ensure work goes on unhindered. In these conditions,you have to be prepared for any situation. You never know what nature has in store for you. Every day is a challenge and you have to be prepared for all the risks that come with such a job.

Jangade is a long way from his home in Bilaspur,Chhattisgarh. In his 13 years with the BRO,he has worked on several other projectsroads,bridges and airports. But a tunnel,he says,is a first. We have developed a deep affection for this tunnel. Every day I hope that I can be part of it till the day of its completion and personally see and supervise the final lining. Its fabulous to be part of a project that will change the life of thousands and lead to progress8230;, Jangade says,stopping to sneeze out some black dust and moving on to the next portion of the tunnel.

- 01

- 02

- 03

- 04

- 05