Three of a kind: the different balls used in Test cricket

With World Test Championships in mind, MCC’s cricket committee proposes standardisation of the red ball

After sourcing raw leather of 4 to 4.5 mm thickness, the Dukes makers compress it down to 3.5mm.

After sourcing raw leather of 4 to 4.5 mm thickness, the Dukes makers compress it down to 3.5mm.

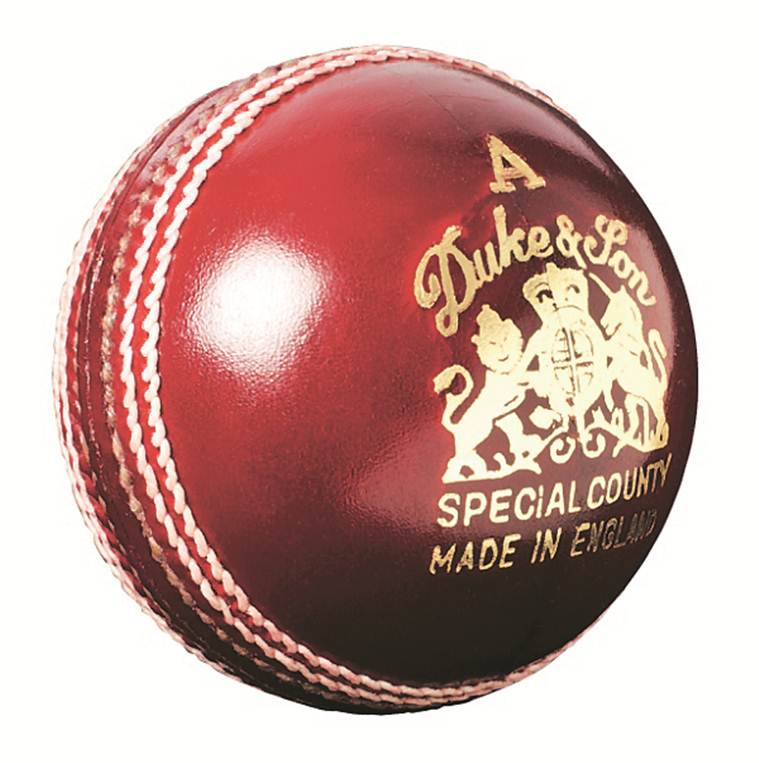

Dukes ball

Made in England

Used in England, Ireland and West Indies.

HOW’S IT MADE: After sourcing raw leather of 4 to 4.5 mm thickness, the Dukes makers compress it down to 3.5mm. The seam is hand-stitched – six rows of threads hold the cork together, creating a tension that allows the ball to retain its characteristic longer and also hold its shape.

TRAITS: It allows the ball to retain its seam for the better part of 80 overs, after which the 2nd new ball is available. This is the reason why quality swing bowlers, who release the ball rather than hit the deck, can make the Dukes ball talk. The leather is polished with a synthetic grease to ensure that the ball doesn’t soak up too much water. Because of the polishing method, the traditional English Alumtine finish, the Dukes have a darker shade.

READ | MCC’s cricket committee proposes standardisation of the red ball

***

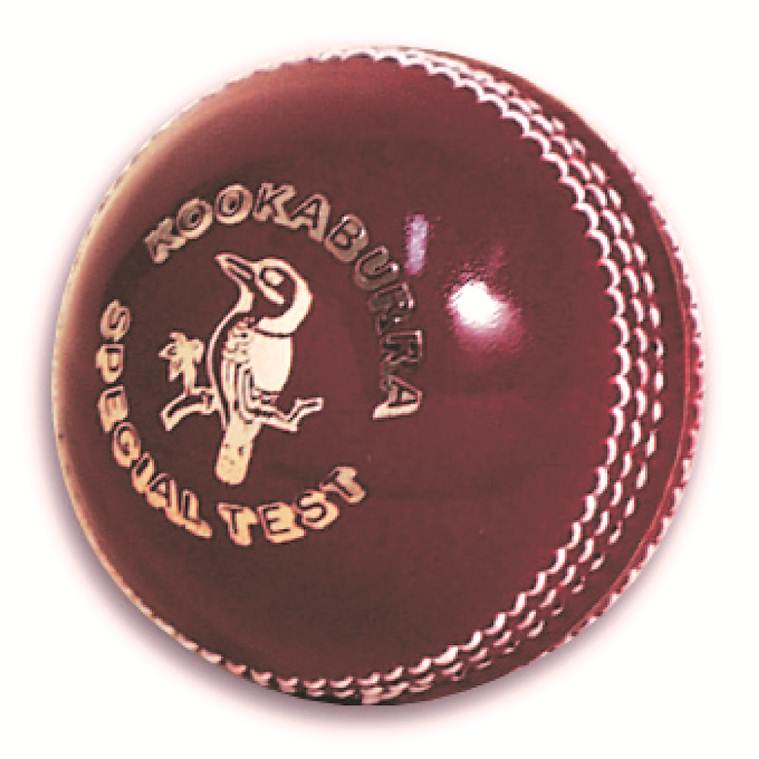

Kookaburra

Made in Australia

Made in Australia

Used in Australia, New Zealand, South Africa, Pakistan, Sri Lanka, Bangladesh and Zimbabwe.

HOW’S IT MADE: The thickness of the leather is minimum 3.5mm. The two rolls of seam are machine-stitched. This is why the Kookaburra has a flat seam.

READ | Standardisation of the red ball: It’s just not Test cricket

TRAITS: In the early overs, the pacers get appreciable swing and seam. But as the seam fades quite quickly, usually after 20 overs, the bowlers become ineffective. The thin seam makes it difficult for finger spinners to grip the ball while wrist spinners are better of. In the absence of swing and seam movement, pacers usually hit the deck. Because the ball is machine-stitched, it’s a little flatter at the top.

***

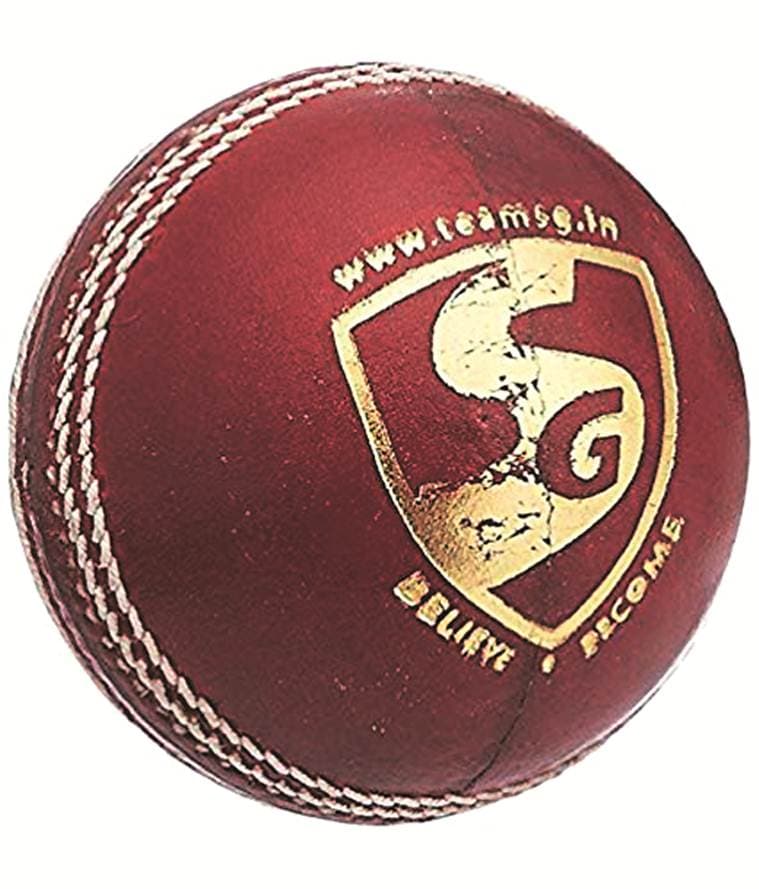

SG

Made in India

Made in India

Used in India.

HOW’S IT MADE: It uses 3.5mm Alumtine leather, a la the Dukes. The seam is hand-stitched and the SG has the most prominent and upright seam which holds up for an entire day’s play.

TRAITS: It’s pronounced seam lasts for close to 90 overs. Initially, the ball doesn’t swing but once the teams start shining the ball on one side, it starts moving in the air. The protruding seam stays upright as it comes out of the seamer’s hand, giving more control over seam and swing. The spinners get a firm grip on the ball and the prominent seam grips the surface better, resulting in bigger turn and bounce. Spinners can also get drift. The SG ball is said to lose its shine quickly, making conventional swing somewhat redundant after a certain period. The upright seam, however, makes reverse swing possible. The earlier SG balls, with a more pronounced seam, had a problem with the seam expansion. Now the seam doesn’t expand too much.

- 01

- 02

- 03

- 04

- 05