Across the world, municipal solid waste and its safe disposal have triggered research by scientists and technologists who want to solve the problem once and for all. Most of the research has focussed on finding solutions for both wet and dry waste and to come up with solutions for municipal landfills and the ever-growing mountains of garbage. (If you missed the earlier stories in this series, click here)

Generation of solid waste, in ever expanding urban spaces, has far exceeded the infrastructure set up to handle them. The need of the hour is to find a solution which would allow for decentralized treatment of wet garbage (preferably at the source of origin), treat landfills and their legacy waste and come up for solutions for multi-layered plastics which ends up in landfills because of difficulties in recycling.

A look at solutions from Pune which might have answers to these questions.

Vaayu, turning waste pickers to energy providers

Priyadarshan Sashrabuddhe’s desire to tackle the problem of organic (wet) waste stemmed from his student days in IIT Bombay. A devout votary of sustainable lifestyle, Sashrabuddhe wanted to come up with solutions for organic waste which would help in its disposal and also have a social impact. In his words, the solution should convert waste pickers into energy providers, allow for decentralised solutions for organic waste and to solve the problem of fossil fuel.

“In a world where there is emphasis on reduced usage of fossil fuels, organic waste can solve problems of cooking fuel in a single household. What is needed is intelligent design and quick solutions which can be implemented in a decentralised manner,” he explained.

Sashrabuddhe’s solution relies on generation of biogas from wet waste but uses a much simpler mechanism to handle and operate. Vaayu, the brainchild of Sashrabuddhe, is a simple mechanism which can be set up at household levels and run on a day to day basis.

Priyadarshan Sashrabuddhe’s desire to tackle the problem of organic (wet) waste stemmed from his student days in IIT Bombay. Express Photo by Pavan Khengre

Priyadarshan Sashrabuddhe’s desire to tackle the problem of organic (wet) waste stemmed from his student days in IIT Bombay. Express Photo by Pavan Khengre

“Vaayu solves the problem of solid waste and access to clean cooking fuel. Biogas generated from organic waste becomes the main cooking fuel,” he said.

Story continues below this ad

Vaayu, or air, involves a special bacterial solution which ‘digests’ the organic waste and generates biogas. The gas generated is stored in an inflated balloon and then supplied through piped installation for cooking. The set includes a digester, where the bacterial decomposition happens and the piped installations which supplies the gas for cooking.

Research and development by Sashrabuddhe has allowed development of a better digester which is much easier to handle and much more efficient from the prototype developed in 2018.

Vaayu, or air, involves a special bacterial solution which ‘digests’ the organic waste and generates biogas. Express Photo by Pavan Khengre

Vaayu, or air, involves a special bacterial solution which ‘digests’ the organic waste and generates biogas. Express Photo by Pavan Khengre

A normal Vaayu installation consumes 2 kg of organic waste to generate enough bio gas to meet the cooking needs for 40 minutes. The liquid by-product is an excellent fertilizer which can be reused. Thanks to the bacterial mixture, the whole process is odourless and hygienic.

Vaayu comes in various sizes which can be as large as 200 kg. Since the design was perfected, Sashrabuddhe has managed to install 300 units in Maharashtra as well as in Udaipur. The installations range from individual homes to institutional set ups like hotels, corporate canteens hostels and others. The company has channel partners in various cities of Maharashtra and is now expanding pan India.

Story continues below this ad

What Sahasrabuddhe dreams of is a social impact wherein the waste collector becomes the energy provider. Over the last two years, Sahasrabuddhe is LPG-free with Vaayu meeting all his domestic energy requirements. “What I really want to do is to have bigger set-ups in housing societies which would be run and operated by the waste collectors. Thus, instead of just waste collectors they should become energy providers,” he said.

Solving the problem of MLP

In the world of recycling, plastic – and its numerous – forms presents the biggest challenge. Thanks to its durability and its almost immortal nature, plastic has become the mythical Lernaean Hydra which is almost impossible to end. Worldwide, research on plastics attracts millions of dollars with scientists, and polymer engineers spending endless nights trying to come up solutions to this problem.

Multi layered plastics, or MLP, are the most commonly used packaging material. Being easy to use, food manufacturers prefer this to pack their food to retain its freshness and to prevent spoilage. What was the biggest boon for the material is now the biggest stumbling block for recyclers. Banker turned entrepreneur Anish Malpani, founder of Ashaya, is on a mission to solve this problem and also have a social impact on ground.

Story continues below this ad

Before the 33-year-old Malpani decided to hang up his corporate shoes, he was working in the United States in finance with a top media company. His desire to work in the impact space saw him pursuing what he called “Custom MBA” which saw him working in Africa and Latin America. With real-time experience under his belt, Malpani landed in India in 2019 to identify a sector where his work can have the biggest impact both socially and individually.

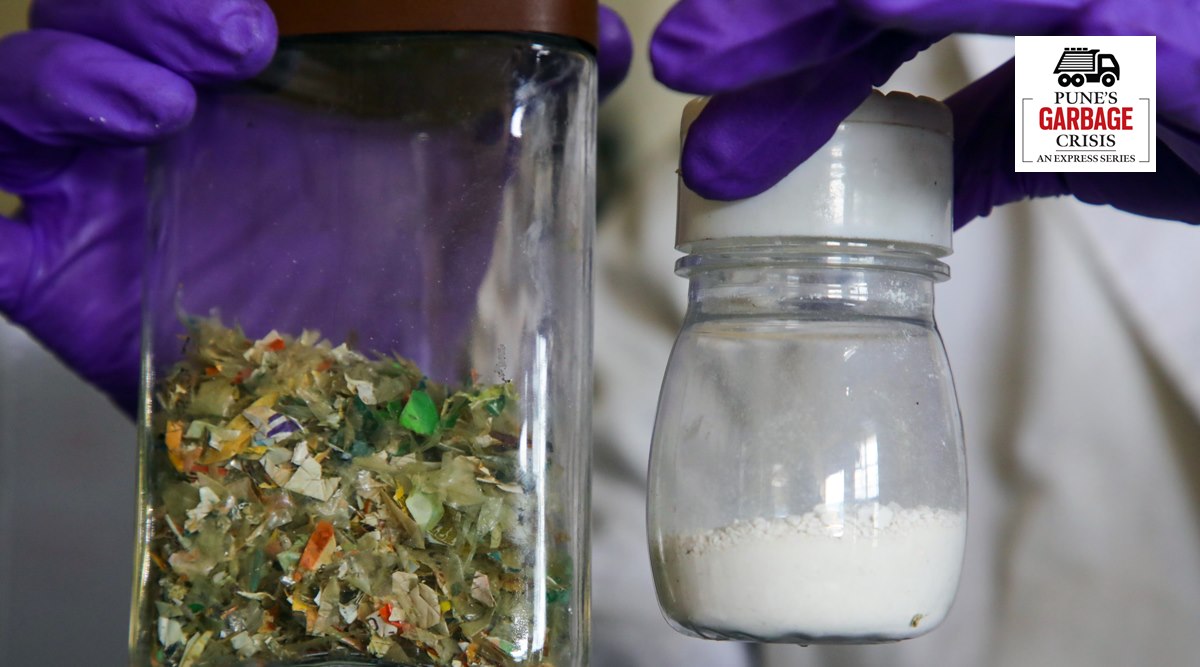

Multi layered plastics, or MLP, are the most commonly used packaging material. Express Photo by Ashish Kale

Multi layered plastics, or MLP, are the most commonly used packaging material. Express Photo by Ashish Kale

“Solid waste management presents the greatest potential given the multifaceted problems it presents. In the world of recycling, MLP is the bug bear which has little or no solutions. Most of it ends up in the landfills which is really not a solution,” he said.

MLP presents unique problems — the material is produced by fusing together or sticking together different types of material. A single packet of potato chips would have layers of plastics, and metal stuck together with adhesive or fused together. For recycling, this becomes a nightmare and ends up in the landfill. What Malpani, in his laboratory in the Bhosari industrial unit, plans to do is to convert this MLP into high quality material.

Extracting high quality material, Malpani says, is possible through a complex process which involves chemical and polymer engineering. The recycled material that is extracted can then be moulded into products using customized, 3D-printed moulds.

Story continues below this ad

The recycled material that is extracted can then be moulded into products using customized, 3D-printed moulds. Express Photo by Ashish Kale

The recycled material that is extracted can then be moulded into products using customized, 3D-printed moulds. Express Photo by Ashish Kale

“In the world of plastics, PET bottles have a higher recycling rate. This is because it is made up of single material. In our laboratory we have extracted high quality material from MLP which the penultimate steps towards products,” he said.

Malpani’s business model has the involvement of waste pickers who provide the MLP as well as a complex marketing chain where in the finished product is sold. Malpani hopes to spread across the country with mini manufacturing hubs in different regions. This will decentralise the problem of waste and help eliminate the need of a landfill.

“We are still in R&D stage and hope to launch our first product made from recycled material by the end of the year,” he said.

Missed the Pune garbage series? Read all the stories here

Story continues below this ad

Writeback: Send in your comments, on this report and others, to pune@expressindia.com

Priyadarshan Sashrabuddhe’s desire to tackle the problem of organic (wet) waste stemmed from his student days in IIT Bombay. Express Photo by Pavan Khengre

Priyadarshan Sashrabuddhe’s desire to tackle the problem of organic (wet) waste stemmed from his student days in IIT Bombay. Express Photo by Pavan Khengre Vaayu, or air, involves a special bacterial solution which ‘digests’ the organic waste and generates biogas. Express Photo by Pavan Khengre

Vaayu, or air, involves a special bacterial solution which ‘digests’ the organic waste and generates biogas. Express Photo by Pavan Khengre Multi layered plastics, or MLP, are the most commonly used packaging material. Express Photo by Ashish Kale

Multi layered plastics, or MLP, are the most commonly used packaging material. Express Photo by Ashish Kale The recycled material that is extracted can then be moulded into products using customized, 3D-printed moulds. Express Photo by Ashish Kale

The recycled material that is extracted can then be moulded into products using customized, 3D-printed moulds. Express Photo by Ashish Kale