Opinion What is the solution to India’s garbage disposal problem?

A consumption tax based on concrete aspects of sustainability, and its local devolution, would create the right incentives for a scientific analysis of garbage and the logistics of its disposal.

We see that the revenue per employee is about Rs 2 crore, while for a permanent employee this figure is about Rs 6 crore. (Illustration by C R Sasikumar)

We see that the revenue per employee is about Rs 2 crore, while for a permanent employee this figure is about Rs 6 crore. (Illustration by C R Sasikumar) This monsoon, several parts of India have found themselves literally swimming in filth and sewage. Gutters have choked with garbage, plastics being the primary culprit. Single-use plastic carry-bags have been singled out for particular attention and regular meetings have been held to educate – as well as admonish — people about their use. Thus once more, the buck has stopped at the doorstep of the people – their good behaviour is seen as the key to change.

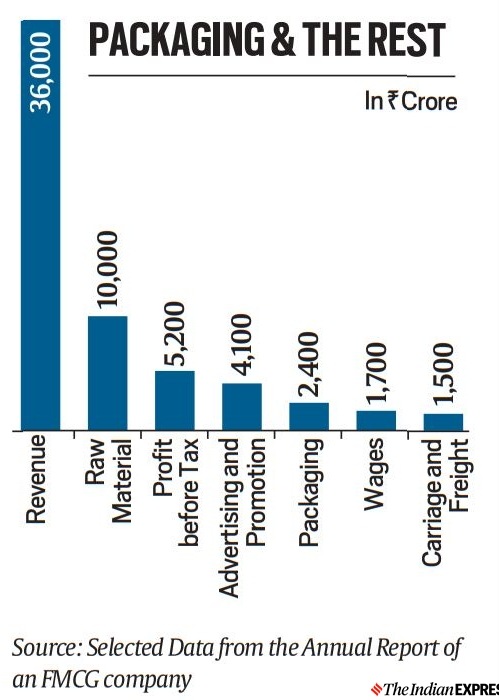

A cursory exploration of a clogged gutter will, however, show that branded packaging material — metal foil wrappers, bottles and boxes of various grades of plastics — are a substantial part of the mess inside. So, who is going to clean that up? For this, we need to understand the science and economics of how this packaging matter got there. Let us begin with some data (see accompanying table) taken from a recent annual report of a large consumer goods (FMCG) company whose products — shampoos, soaps, ketchup, squashes etc — are available all over India. The company had 18,000 employees of which 5,800 employees were permanent. The CEO, a Harvard graduate, was paid 170 times the median salary.

There are many interesting things here. We see that the revenue per employee is about Rs 2 crore, while for a permanent employee this figure is about Rs 6 crore. Wages constitute less than 5 per cent of the revenue but spending on promotion and advertising is more than double of that. This is a transfer of wealth from the consumer, both rural and urban, to an elite urban class — the so-called creative people.

Let us come to garbage and sustainability — the expenditure on packaging, carriage and freight. The freight expenditure tells us that out of every Rs 100 of the company’s product that we buy, Rs 5 has gone up in vehicular smoke and Rs 8 for the package that we hold in our hand. This packaging is required because the products must have a long shelf life, and withstand heat, sunlight and rough handling during freight.

So where should this piece of plastic go? As usual, the Centre and state governments have grandiose laws, but there is little scientific know-how or bureaucratic ability to implement them. According to the law, the ultimate manufacturers (UMs) of the plastic films — the raw material for the much-reviled carry-bags and also the much larger volume of branded packaging — are responsible for the collection of this waste and its processing. They must set up collection networks and work with state pollution control boards and the city and town administrations to ensure that this waste reaches recyclers and manufacturers. The rural regions are, of course, ignored.

Garbage and sustainability — Revenue generated and the expenditure on packaging, carriage and freight.

Garbage and sustainability — Revenue generated and the expenditure on packaging, carriage and freight.

This system has not worked for a very simple reason. While Rs 8 out of 100 was spent on packaging the product, the cost of the packaging materials is barely Rs 1. The rest of the cost is in shaping this raw material into packaging units — filling these up and sealing them, labelling and branding, and finally putting them into bulk cartons ready for transport. Given the volumes at the FMCG manufacturing plant, hundreds of shampoo bottles need to be filled per minute and soaps need to be packed. The machines which do this are some of the most intricate combinations of sensors and control systems. Most of them are imported and contribute significantly to the cost.

Of the Re 1 of the reusable material, even with the most advanced recycling technology, the value of that piece of garbage in our hand to the ultimate manufacturer is less than 50 paise. Therefore, it is simply not economical to transfer the waste back to the manufacturer. Hence, only where this waste is concentrated and there are abjectly poor people available to segregate, can supply chains exist to take it back to the chemical plants. This is why the garbage dumps, ragpickers and the neighbourhood kabadi shops are necessarily the only viable last mile of our recycling system.

For Chiplun, a taluka town in Ratnagiri district of Maharashtra, this means about 75 per cent of the plastic garbage is left on the streets, blowing in the wind, clogging up gutters, strewn on playgrounds and beaches, reaching streams and rivers, and finally the sea. The remaining 25 per cent is collected by the city’s stressed garbage collection system and a few good Samaritans at the Sahyadri Nisarga Mitra — an NGO. Much of this accumulates in ever-rising garbage dumps or is incinerated and the rest goes back to the ultimate manufacturer. As with most public services, such as education or drinking water, the goodness of heart of a few and the noble intentions of our leaders, rather than a professionally run system, form the basis of delivery of this important environmental service.

What is to be done? One attempt in Maharashtra addresses the most visible waste, PET bottles and milk bags, and puts a large value, Rs 1 and 50 paise respectively, as the collection price to be paid by the bottlers and milk producers to anybody who presents them with the waste. This has worked with PET bottles, simply because they are easily collected in bulk, at railway stations and restaurants, and easily picked up in garbage dumps. But that has not happened with milk bags. Even with PET bottles, the artificially large price of Rs 1 exceeds the production cost of 60 paise and thus there is money to be made in making fresh PET bottles.

But there is an important insight here of holding the product manufacturer, and not the packaging material manufacturer, responsible for the disposal of waste. Just as it took Rs 8 to convert the packing material into a packaged product and Rs 5 to transport it and put it in our hands, it will take a commensurate amount of money — say Rs 3 — to take it back to its ultimate source. This may be implemented as a sustainability tax on the packaging and carriage cost components of a given product. Given the elaborate bureaucratic machinery of the GST and the formal nature of the dealer network of large FMCG companies, this tax can be easily administered and transferred to the districts and towns. Chiplun would then get about Rs 2.1 crore per annum to address its garbage disposal problem.

Such a consumption tax based on concrete aspects of sustainability, and its local devolution, would create the right incentives for a scientific analysis of garbage and the logistics of its disposal. It will also create a clutch of professional companies who specialise in this sector and provide their services to the hundreds of cities and towns of Maharashtra.

It will also help citizens of Chiplun ask the right questions about the items they consume and the production processes behind them. Do I really need shampoo manufactured in Gujarat or potato wafers from Kanpur? Do they offer superior quality or better hygiene? Or is it merely branding? Is it not possible for young entrepreneurs in SMEs of Ratnagiri to manufacture good quality shampoo but package and sell it differently? Does it need a revenue of Rs 2 crore to create a job?

In fact, this sets up a different agenda — of communities and regions that are atmanirbhar about simple things. Of a decentralisation of sophistication that would create more jobs for our youth and give them more dignity. And improve the quality of our lives and help preserve the environment.

The road to sustainability goes through such cultural questions.

The writer is Professor, IIT Bombay. He wishes to thank Bhau Katdare of Chiplun for many insights