Despite concerns flagged at the highest levels in the government over market concentration in India’s solar PV module industry and its potential to inflate household electricity tariffs, the Ministry of New and Renewable Energy reimposed its mandate requiring solar projects to source modules exclusively from a government-approved list of domestic manufacturers starting April 1.

Prior to the reimposition of the Approved List of Models and Manufacturers (ALMM) order, former Union Minister of Power and New and Renewable Energy R K Singh and the central public sector enterprise SJVN Ltd had explicitly flagged concerns around domestic manufacturers engaging in “excessive profiteering” and warned of higher tariffs for future projects fuelled by more expensive domestic modules, according to documents accessed by The Indian Express under the RTI Act.

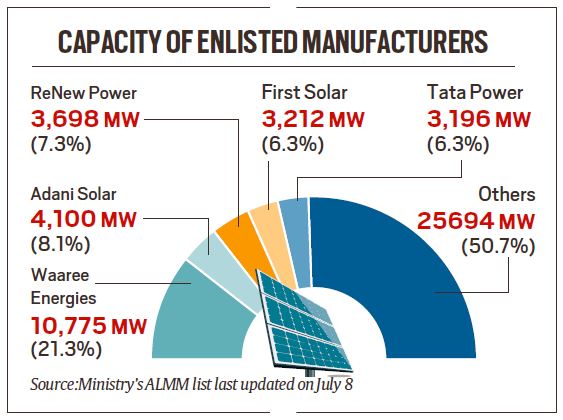

Notably, companies linked to just five manufacturers — Waaree Energies, Adani Solar, Nasdaq-listed ReNew Power, US-based First Solar and Tata Power — control nearly half of the current capacity listed on the ALMM, first issued by the ministry in March 2021.

Domestic manufacturers are now charging 90% more for solar modules compared to their foreign competitors, based on recent estimates.

The price gap between domestic and imported modules, mainly from China, has widened significantly in recent years. Compared to 6% in the first quarter (Q1) of FY22, domestic modules turned 50% more expensive in Q1 FY24, before nearly doubling in Q1 FY25, according to an analysis of CRISIL data.

The ALMM order mandates all government-assisted or -associated solar projects to use only enlisted modules, effectively barring the use of imported modules in most projects. The order aims to bolster domestic clean technology manufacturing and enhance energy security by reducing import dependence.

Former Minister, SJVN flagged concerns

In March 2023, the ministry put the ALMM order in abeyance for a year after the then Union Minister R K Singh noted that it was “imposed prematurely” due to insufficient domestic manufacturing capacity, which in turn was slowing the addition of solar capacity, according to file notings accessed by The Indian Express.

Story continues below this ad

Singh also noted that the order was not “brought in to enable some manufacturers to exploit the people of India by charging extortionate prices”, which in turn can become “a burden on the people, because the people will have to pay a higher cost for power”.

ExplainedRising cost difference

DOMESTIC solar modules are now 90% more expensive than imports, with prices reaching 18 cents per watt in June compared to 9.1 cents for imported modules. This gap has widened since FY22, when domestic prices were 6% higher than imports.

In the final months of FY24, when the ministry was reviewing ALMM applicability for FY25, concerns around higher cost of domestic modules persisted. In February this year, Singh noted that module manufacturers import cells from China and only assemble them in India. Currently, cell manufacturing capacity in India is below 10 GW.

“…this is not Make in India and… they charge hefty margin for the same. It has been stated that the present price of cells in China is around 6 cents, that after imposition of 25% of duty which we have put in place it comes to 7.5 cents. The fabrication cost is not more than 7-8 cents. Therefore, the modules should be available for 16 cents; however, the module manufacturers are charging 23-24 cents. This is excessive profiteering. Protection has not been given to them to overcharge the people. The higher prices of module lead to higher price of electricity for the people,” Singh said in a signed note.

Singh was not alone in voicing these concerns. SJVN Ltd, a public sector enterprise in which the central government owns a 55% stake, formally appealed to the ministry for a nine-month extension of the abeyance order.

Story continues below this ad

“It is humbly submitted that the non-extension of procurement of Solar PV Modules for the manufacturers appearing in the ALMM will derail the ambitious target of GOI to develop 50 GW solar capacity and will also affect the tariff for upcoming projects,” SJVN’s then CMD Geeta Kapur wrote to the ministry on February 8.

The ministry, former minister Singh and SJVN did not respond when The Indian Express sought their comments.

The ministry reimposed the ALMM order from April 1, expanding it to include previously exempt open access and captive projects despite industry appeals. In May, it exempted export-oriented green hydrogen projects, which will potentially require 125 GW of renewable energy by 2030.

The order was reimposed because senior officials in the ministry believed that the enlisted capacity of around 50 GW was sufficient and that the duty-free import of solar modules from ASEAN countries was detrimental to domestic producers.

Story continues below this ad

‘Chinese overcapacity is distorting prices’

“The reality is that too many in India’s solar industry are willing to sacrifice our country’s strategic objectives in exchange for continued access to Chinese solar panels, which are being dumped in India. It’s unfortunate that these players see distorted pricing driven by Chinese overcapacity as the benchmark rather than recognising the political, commercial, and ethical risks posed by deepening their – and India’s — reliance on China’s solar supply chain,” Sujoy Ghosh, V-P and MD for India at First Solar told The Indian Express.

In 2022, the industry withdrew an anti-dumping case it had initiated with the Directorate General of Trade Remedies (DGTR) after the imposition of a 40% basic customs duty (BCD) on imported solar PV modules, which remains in effect, “alleviated the price pressure being suffered by the domestic industry”.

Ghosh also said that higher module prices and power tariffs are not correlated. “Let’s look at the data: in the past two years, prices of solar power purchase agreements (PPA) increased 8.5%, from an average of Rs 2.3-2.4 per kilowatt-hour to an average of Rs 2.5 to 2.6 per kilowatt-hour. Conversely, solar module prices decreased by 57% in the same period. The reality is that there is no tangible correlation between higher module prices and PPA prices,” he said.

Domestic modules 90% more expensive

According to data on domestic and imported prices of monocrystalline modules — currently the most widely used type — compiled by a CRISIL subsidiary, the price disparity between domestic and imported modules has reached unprecedented levels.

Story continues below this ad

In June 2024, the average cost of imported modules on a cost, insurance, and freight (CIF) basis, before the application of any local taxes or duties, stood at 9.1 cents per watt. In stark contrast, domestic modules were priced at 18 cents per watt, effectively making them at least twice as expensive as their imported counterparts.

This is a sharp divergence from just three years ago. In FY22, the average cost of imported modules was 28.7 cents per watt, compared to 26.9 cents per watt for domestic modules — nearly at parity. Module costs are a critical component of solar project economics, often accounting for 50% to 60% of the total cost of commissioning a project.

While module prices have fallen globally, including in India, the decline has been far more rapid in China, driven by economies of scale and a swift expansion of manufacturing capacities. One large domestic module manufacturer told The Indian Express that it could take at least 2-3 years for made-in-India modules to become more competitive against imported ones.

Domestic capacity set to grow further

While the currently enlisted capacity on the ALMM stands at around 50.6 GW, some industry experts expect the available capacity to be much lower.

Story continues below this ad

“After accounting for operational efficiency, exports and low-quality modules, the supply of high-efficiency domestic modules to the Indian market will only be around 20-22 GW, much less than the annual solar installation target of 30-35 GW, apart from another 5 GW target for rooftop solar,” a report released in May by the Institute for Energy Economics and Financial Analysis and JMK Research said. The report said that ALMM should include leading global manufacturers until March 2026.

In a file noting, Bhupinder S Bhalla, Secretary, Ministry of New and Renewable Energy, said that the capacity is expected to rise to 90-100 GW by around 2026 on account of commissioning of manufacturing capacities awarded in the Production Linked Incentive (PLI) scheme for solar PV modules.

Till now, the ministry has announced incentives for 48.3 GW of module manufacturing capacities under the PLI scheme. Of the total awarded capacities, 18.9 GW or 39 per cent has been awarded to the top five manufacturers namely Waaree Energies, ReNew Power, First Solar, Adani Solar, and Tata Power for incentives worth roughly Rs 5,685 crore.

These companies collectively hold 49% of the total enlisted capacity on the ALMM, with Waree leading with 10.7 GW, followed by Adani’s 4.1 GW, and ReNew’s 3.7 GW.

Story continues below this ad

Under the PLI scheme, the government has also awarded a Reliance Industries Ltd (RIL) subsidiary 10 GW of manufacturing capacity for incentives worth Rs 5,015 crore. RIL is targeting to commission 20 GW of manufacturing capacity by the end of FY25, according to its latest annual report.

‘ALMM to prevent circumvention of BCD’

Bhalla also noted that the ALMM order is “the only way” to prevent the circumvention of BCD by importing from ASEAN countries. “As per import data of India for 2023-24 (April-November), out of import of USD 2081 million worth of solar PV modules, 38% i.e. around USD 780 million emanated from ASEAN countries with zero BCD under India-ASEAN FTA (free trade agreement). ALMM is the only way to prevent circumvention of the 40% BCD through ASEAN countries,” he wrote.

According to official trade data, in FY24 India imported solar PV modules and panels worth Rs 36,134 crore, with modules worth Rs 23,678 crore or 66 per cent coming from China. Solar PV modules from China attract BCD.

In April this year, after the reimposition of the ALMM order, the total value of module imports increased by 107 per cent to Rs 2,158 crore compared to April 2023, largely on account of pending deliveries. In the following month, the value of imports dropped by 65 per cent to Rs 516 crore compared to May 2023.