MIT engineers develop paper-thin solar cells to turn any surface into a power source

MIT researchers have developed an ultrathin solar cell that is eighteen times lighter per watt generated compared to conventional silicon photovoltaic solar panels.

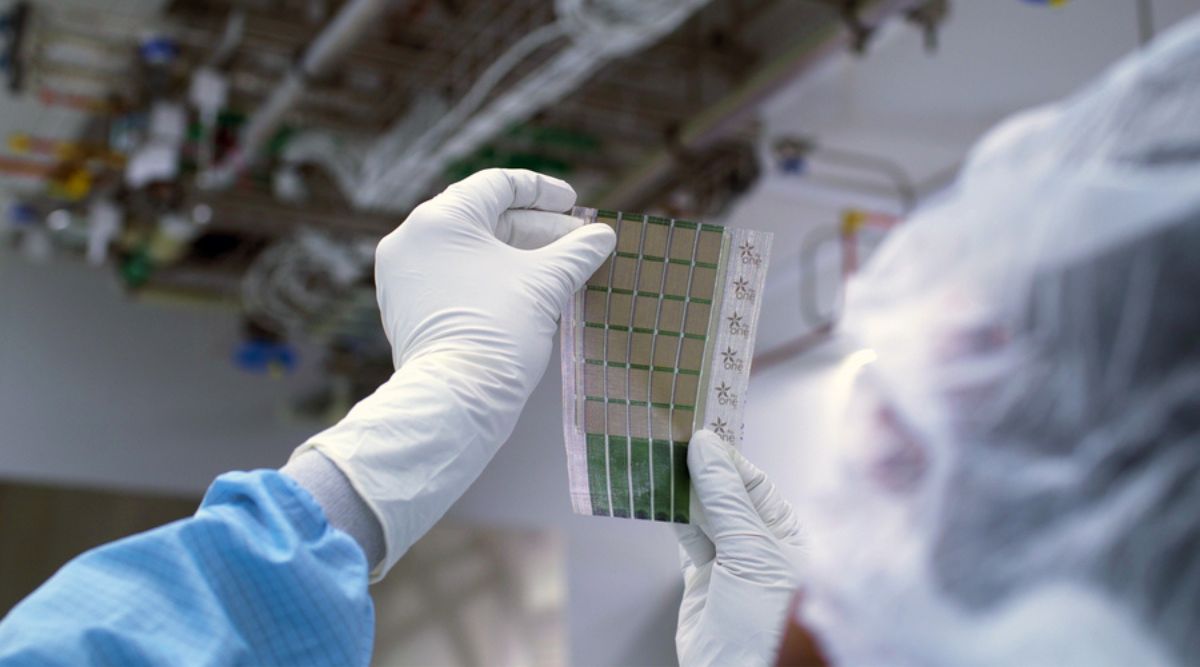

MIT Solar Cell Research: The researchers used nanomaterials in printable electronic inks to create this novel solar cell device. (Image credit: Melanie Gonick, MIT)

MIT Solar Cell Research: The researchers used nanomaterials in printable electronic inks to create this novel solar cell device. (Image credit: Melanie Gonick, MIT) Researchers at MIT have developed an ultra-thin and ultra-light solar cell that can be used to turn almost any surface into a solar power source. The flexible solar cells are much thinner than human hair and are glued to a lightweight fabric to make it easier to install them on any fixed surface.

“The present version of our new lightweight photovoltaic (PV) cells is not as efficient in power conversion as silicon PVs, but they weigh much less. In the short run, they would not be used to replace conventional silicon PV installations, but to provide power where silicon PVs cannot be easily installed,” said Vladimir Bulović, lead author of the article on the research published in the journal Small Methods, to indianexpress.com over email.

“For example, they can be used to deliver solar electricity in places that are hard to reach. Being 18 times lighter than silicon PV modules per Watt generated, our PV modules can be easily delivered and installed in remote villages. As our technology gets improved, we expect it will reach the efficiencies presently generated by silicon PVs. At that point, our flexible PV modules can be considered a replacement for silicon PVs,” added Bulovic.

Making the ultra-thin solar cells

The researchers used nanomaterials in printable electronic inks to create this novel solar cell device. They used a “slot-die coater” to deposit layers of electronic materials onto a substrate that is only 3 microns thick. They then used a screen printing technique to print an electrode and deposit on the substrate to complete the solar cell. At this point, the printed module is about 15 microns in thickness, and researchers can peel off the plastic substrate to get the device. For comparison, human hair is around 70 microns thick on average.

But this ultra-thin freestanding module itself is difficult to work with, as it can easily get torn or damaged in other ways. To counter this problem, the researchers turned to a material known commercially as Dyneema — a special kind of fabric that only uses 13 grams per square meter.

According to MIT, the fibres of the fabric are so strong that they were used as ropes to lift a sunken cruise ship from the bottom of the Mediterranean sea. They adhered the solar device to this material using a UV-curable glue, resulting in an ultra-light and durable structure that can be used for various purposes.

Versatility, durability and future research

Conventional photovoltaic solar cells are fragile, which is why they are encased in heavy glass and metal framing. This puts great limits on where such solar cells can be installed and deployed. This is why there has been renewed interest in developing such versatile ultra-thin solar cells. For example, earlier this year, Dartmouth researchers developed a new flexographic printing process to deposit perovskite solar cells on almost any material.

The MIT researchers tested the durability of the new devices they developed, and found that the cells retained more than 90 per cent of their initial power generation capabilities even after the fabric was rolled and unrolled more than 500 times. However, they would still need to be encased in another material to protect them from the elements.

The researchers told indianexpress.com that additional work would be required to make these cells more robust. “We are developing lightweight packaging technology that would be flexible and mechanically robust, which would enable us to maintain the format of the present PV,” Bulović said.

Once the packaging technology is developed, the researchers envision many uses for the material. For example, it can be installed on the sails of a boat to provide power at sea. It can also be used on tents and tarps used during disaster recovery operations, or even on drones to extend their range.