Grin and beer it

Life was well set for IIM graduates Suketu Talekar and Prateek Chaturvedi and VLB Berlin graduate Oliver Schauf,a German national,until one fine day,they decided to quit the well-paying jobs and venture into manufacturing beer.

Life was well set for IIM graduates Suketu Talekar and Prateek Chaturvedi and VLB Berlin graduate Oliver Schauf,a German national,until one fine day,they decided to quit the well-paying jobs and venture into manufacturing beer. Four and a half years later,the trio are on a high with the first ever craft beer unit- Doolally set up and functional at Corinthians Boutique Hotel in Pune.

It seemed as if we were under the influence of alcohol when we decided to call it quits in our previous job. Because discussing with friends about starting a venture and following it up on a day-to-day basis are two entirely different things. But all the efforts have finally paid off and we are one of the first craft beer manufacturers in the state and probably second in the country, says Prateek Chaturvedi.

There is an interesting story behind the name Doolally too. Apparently in the British era,the Devlali camp near Nasik was the place soldiers would rest during their breaks from the fields. The best of beer was served to these soldiers. The name Doolally became popular after the British soldiers pronounced Devlali in that manner. In fact they would say -Lets have beer and go Doolally, smiles Chaturvedi.

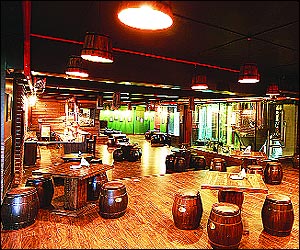

Having a beer in Doolally is a unique experience that starts with the unveiling of the process of beer making in large steel vessels placed right by the side of the serving area. It is like making tea. We use malted grain such as Barley wheat instead of chai ka patti, says Talekar as he explains the intricacies,We buy the malts from Germany and adding it to water,we heat the mixture to 60- 70 degrees Celsius. This breaks down the sugar. The extraction process followed by this includes a regular filtering that takes out the essence of the malt. The liquid is then cooled and sent for pitching or fermentation where we add yeast to it. Yeast eats the sugar and converts it into carbon dioxide and alcohol. Last but not the least,the final fermentation differs from beer to beer. For instance if it is bottom fermentation beer or lagers as it is technically called,it takes between seven to 10 days. On the other hand for top fermenting beers like Guinness beer and wheat beer,it takes three- four days. We also adds hops- specially dried flowers imported from Czechoslovakia and Baveria at various stages during the process to add flavour to the beer, smiles Talekar.

With Pale Lager,Dark lager,Wheat Beer and Apple cider as the current offerings on their menu cards,the trio is all out experimenting with the drink they love the most. We plan to promote the same model at various locations in the country. Experimenting with beer,we plan to get this country out of Lager beer,the only choice available to beer lovers and make more choices available to them, promises Talekar.