The Union Cabinet on Friday cleared a Rs 22,919 crore incentive scheme for manufacturing electronic components, spread over a period of six years. The scheme aims to deepen India’s presence in global value chains, while increasing domestic value addition in the country.

The government is hoping that at least 91,600 direct jobs will be created as part of the scheme, and has tied participating entities’ yearly subsidies to the number of jobs they create. The scheme is expected to generate production of Rs 4.56 lakh crore and bring in incremental investment of Rs 59,350 crore.

The components that the government is looking to target through the scheme include display modules, sub assembly camera modules, printed circuit board assemblies, lithium cell enclosures, resistors, capacitors, and ferrites, among others. These are used in gadgets like smartphones and laptops, and appliances like microwave ovens, refrigerators and toasters, among others.

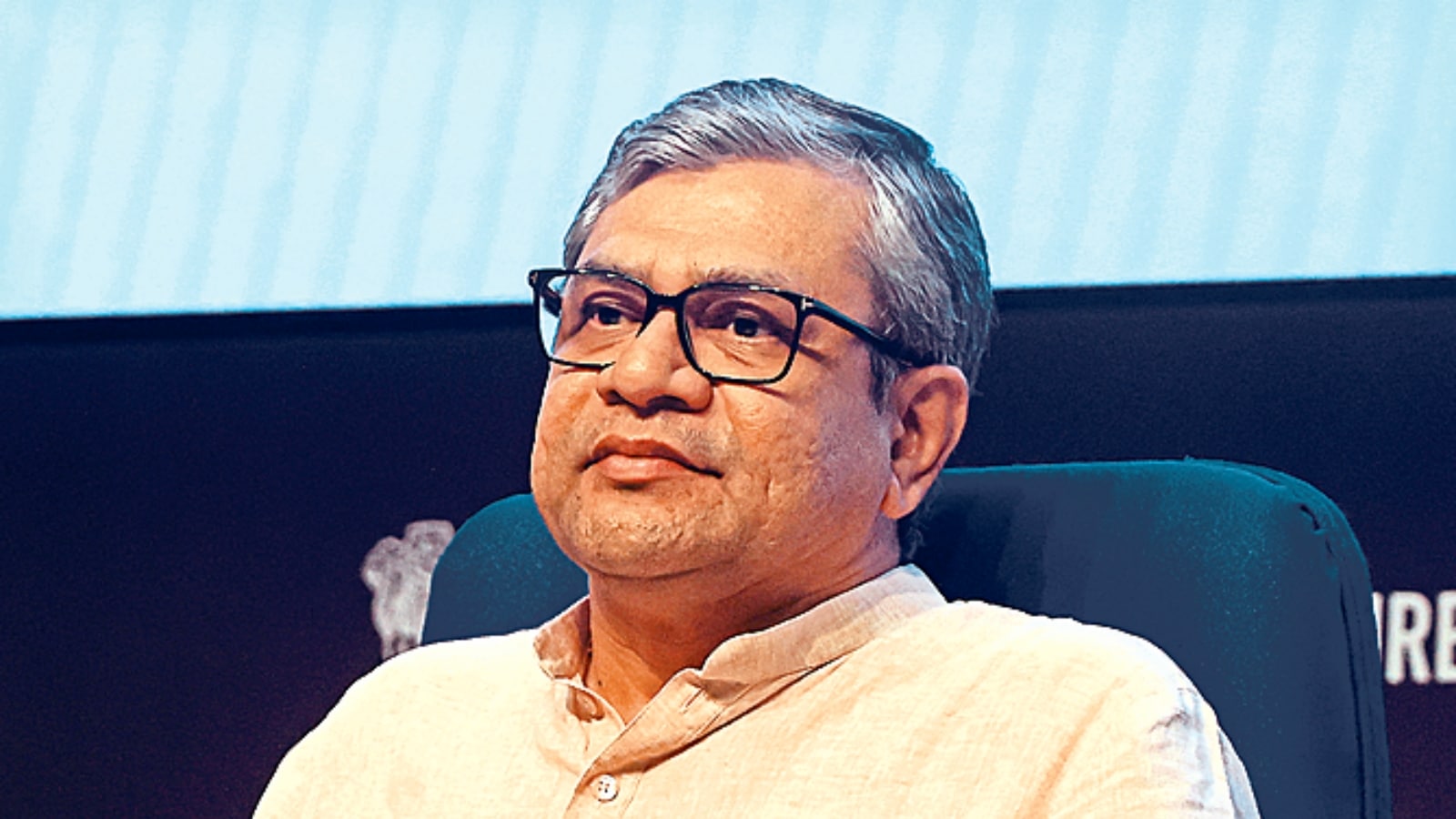

“Components import will reduce after this scheme. We need to come out of the import substitution mindset and go forward with export led promotion. Viability comes after large scale manufacturing. Electronics manufacturing is around $120 billion right now and we are targeting that to grow to $500 billion in the coming years,” Union IT Minister Ashwini Vaishnaw said.

This incentive scheme differs from the government’s earlier production linked incentive (PLI) scheme for electronics manufacturing in how participating companies can avail subsidies. Incentives have been linked to three key parameters: annual employment generation, capital expenditure needs and annual production.

Currently, electronics is among India’s three largest exported commodities, valued at Rs 2.5 lakh crore. That is likely to double in the next four years, Vaishnaw said. He added that to further aid electronics manufacturing, the IT Ministry is in discussions with the labour, commerce and finance ministries to figure out labour reforms specific to the sector, resolve classification of components, and rationalisation of import duties.

Story continues below this ad

The components incentive scheme is a crucial next step as the PLI scheme for smartphone manufacturing is nearing its sunset. Despite getting companies like Apple and Samsung to localise some of their overall assembly in India, the domestic value addition has been relatively low — around 15-20 per cent — with the government hoping to raise it to at least 30-40 per cent.

Alongside the incentive scheme for semiconductors, the government has now launched support for practically all layers of electronics manufacturing, making the sector a crucial growth driver for the Indian economy. China, which has had a decisive lead in the electronics components sector for several decades now, has a domestic value addition of around 38 per cent.

In an internal assessment carried out by the IT Ministry last year, the government had identified a “huge” demand-supply gap in the electronic components sector — to the tune of $100 billion for domestic consumption alone, and $140 billion if India wants to export some components. That would be almost 10 times of India’s current domestic capacity. In 2022-23, the country’s electronic components production stood at $10.75 billion, accounting for only about 10 per cent of total electronics production.

According to the assessment, which The Indian Express reported last August, the government has identified three key challenges in terms of electronic components manufacturing.

Story continues below this ad

First, the current lack of domestic scale in the country.

Second, a high investment to turnover ratio — in terms of finished products such as smartphones, which is what India is currently focusing on, every rupee of investment can bring it around Rs 20. However, in the case of electronic components, every rupee of investment will bring around Rs 2-4.

Third, India has high domestic demand, because of which a large chunk of components are being imported: electronics is the second largest import commodity after oil, accounting for nearly 75 per cent of the total electronics production in India.

Going by this trend, component demand is expected to reach $160 billion by 2028-29. “As component imports continue to grow at around 12 per cent, our component production with exports would have to grow by a CAGR of more than 53 per cent to meet demand,” the ministry’s internal assessment said. This is why it is critical for the country to work out a domestic manufacturing scheme in the components sector.

Story continues below this ad

The assessment acknowledged that while the PLI scheme for smartphones has resulted in a near tapering of imports of finished products, import of key components and sub-assemblies, including integrated circuits, increased from $29 billion in FY21 to $46.5 billion in FY23.