Explained: What Digital morphing wing can it mean for future aircraft

The “digital morphing” wing can change shape to control the plane’s flight. The new approach to wing construction could afford greater flexibility in the design and manufacturing of future aircraft, say researchers.

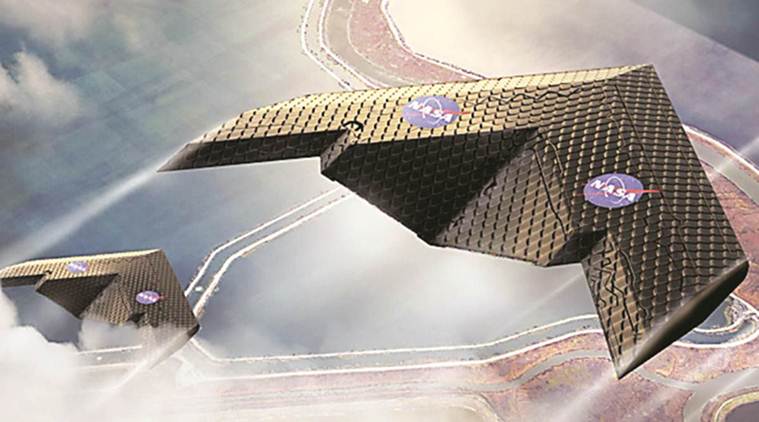

An artist’s concept of the new design for an aircraft wing, whose changing shape can control flight . 9Eli Gershenfeld/NASA Ames Research Center)

An artist’s concept of the new design for an aircraft wing, whose changing shape can control flight . 9Eli Gershenfeld/NASA Ames Research Center)

A team of engineers has designed a radical kind of airplane wing, assembled from hundreds of tiny identical pieces. The “digital morphing” wing can change shape to control the plane’s flight. The new approach to wing construction could afford greater flexibility in the design and manufacturing of future aircraft, say the researchers, including from the Massachusetts Institute of Technology and NASA, who have published their concept in the journal Smart Materials and Structures.

Conventional wings require separate movable surfaces to control the roll and pitch of the plane. The new assembly system, on the other hand, makes it possible to deform the whole wing, or parts of it.

This is important because each stage of a flight — takeoff and landing, cruising, manoeuvring etc — has its different set of optimal wing parameters. A conventional wing is a compromise that is not optimised for any of these stages, and therefore sacrifices efficiency, the researchers point out. A constantly deformable wing, however, could provide a much better approximation than a conventional wing of the best configuration for each stage.

The team has designed a system that automatically responds to changes in the wing’s aerodynamic loading conditions by shifting its shape — a sort of self-adjusting, passive wing-reconfiguration process. The wing is made deformable by incorporating a mix of stiff and flexible components in its structure. These tiny sub-assemblies are bolted together to form an open, lightweight lattice framework.

The framework is then covered with a thin layer of similar polymer material. The result is a wing that is much lighter, and thus much more energy-efficient, than those with conventional designs.

The researchers explain that the structure, comprising thousands of tiny triangles of matchstick-like struts, is composed mostly of empty space; therefore, it forms a mechanical “metamaterial” that combines the structural stiffness of a rubber-like polymer and the extreme lightness and low density of an aerogel.

(Source: Massachusetts Institute of Technology)

- 01

- 02

- 03

- 04

- 05