Mustard face pack, ma146;am?

Blame it on Hindi movies for limiting our appreciation of mustard fields to their beauty. And thank whichever superior creature you believe ...

Blame it on Hindi movies for limiting our appreciation of mustard fields to their beauty. And thank whichever superior creature you believe in that the scientists at the Central Institute for Post-Harvest Engineering and Technology CIPHET can see beyond Kajol and DDLJ 8212; and envision sauces and beauty masks as byproducts of mustard oil.

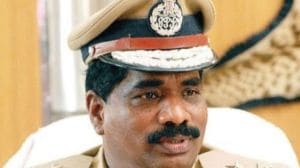

Actually, this story unfolds at a much more micro level than the fields. It starts with the tiny grain of the mustard seed. Working with mustard cakes 8212; the coalesced seeds post oil-extraction 8212; scientists realised that they retained much of their oil content. 8216;8216;Traditional extraction processes extract only 35-40 per cent of the oil,8217;8217; says Dr Ilyas, director of CIPHET. 8216;8216;At least 10-15 per cent remains untouched in the cakes, which find no better use than as animal feed.8217;8217;

The monumental waste this finding implied was enough to get the scientific brain cells ticking. 8216;8216;We launched a project to improve the efficiency of the oil extraction. Soon, we realised that it was the husk of the seed that held the key to innovation,8217;8217; says Dr Ilyas.

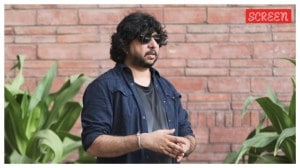

The project team led by Dr O D Vanjari, head of the division of food grains and oil seeds processing, first developed a washing process that removed the husk off each and every mustard seed 8212; no mean task, considering its dimensions.

8216;8216;The husk-free plain yellow seed produced a higher percentage of clear mustard oil, very similar to the imported salad oils. Then we found that the cake could be developed to produce a sauce, which lent itself to two flavours, sweet and spicy. Further, we discovered that bits of the cake could be added to curries and gravies to enhance their flavour and also used in household uptans,8217;8217; says Dr S K Tyagi and Dr Rajesh Vishwakarma, who worked with Dr Vanjari on the project.

Of all the products, though, the CIPHET team is proudest of the mustard sauce, which has been very highly rated by leading chefs of Ludhiana. 8216;8216;Because of the popularity of foods like burgers and hot dogs, the market for mustard sauce, too, is expanding,8217;8217; points out Dr Vanjari. 8216;8216;But perhaps the best thing is that the cost of the sauce-making project is less than Rs 2 lakh.8217;8217;

Not content with the results, the team is now looking to make an organic mosquito repellent from the mustard cake. 8216;8216;Our job is to develop value-added products and help farmers earn more. Our mustard sauce will sell for Rs 25/200 gm; so far a similar product of the same weight was available for Rs 200,8217;8217; says Dr Ilyas.

8216;8216;There will come a time,8217;8217; predicts the CIPHET director, 8216;8216;when the mustard oil will be regarded as a by-product and the value-added products like the sauce and the face pack will be the main revenue earners for farmers.8217;8217;

Either way, the mustard-lined path to the future looks bright.

- 01

- 02

- 03

- 04

- 05