It’s time to build ‘Digital Twins’ of Indian cities to solve the urban crisis: BVR Mohan Reddy, Founder-Chairman, Cyient

BVR Mohan Reddy spoke to indianexpress.com on the social impact of the tech products and solutions that his company is working on, the challenges of bringing such tech to India, and the need for a ‘failure-friendly’ education system.

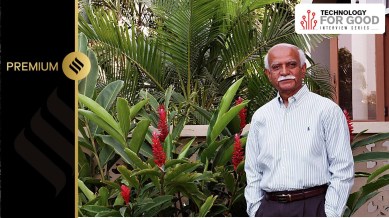

BVR Mohan Reddy has placed India on the global engineering, research and development map. As the founder-chairman of Cyient, a global digital engineering and technology solutions company headquartered in Hyderabad, Reddy has worked to establish a ‘Engineered in India’ brand, providing design engineering services to global companies, including Boeing, Airbus, Pratt & Whitney, Bombardier, Philips, Siemens, and Westinghouse.

Reddy is a pioneer in the computer-aided design/computer-aided manufacturing (CAD/CAM) culture in India, introducing computer systems for design and manufacturing applications as far back as 1982.

A Padma Shri awardee, Reddy holds postgraduate degrees from IIT-Kanpur, and the University of Michigan, USA. He is also the recipient of seven honorary doctorates.

Reddy spoke to Indianexpress.com on the social impact of the tech products and solutions that his company is working on, the challenges of bringing such tech to India, the innovation ecosystem in India, challenges of building supply chains, and the need for a ‘failure-friendly’ education system. Edited excerpts:

Venkatesh Kannaiah: Can you name some themes/products that your company Cyient has been working with international partners which would have an outsized social impact?

BVR Mohan Reddy: One of the highly innovative projects we worked on is on aircraft engines to reduce the carbon footprint and increase efficiency. Most aircraft engines work on a single shaft model, wherein all the systems, compressors, combustors and fans are working at the same speed. This leads to a lot of noise, incomplete burning of fuel, higher carbon emissions and fuel inefficiencies. Single shaft was the issue, but it was thought to be a good solution then.

Working along with the customer we contributed to around 25 per cent of the innovation by introducing a gearbox into the engine for different speeds for every subsystem. More than 60 aircraft operators are using this tech and thousands of engines are being made with this new innovation, leading to almost a 20 per cent savings in fuel and CO2 per trip and with 75 per cent smaller noise footprint.

We worked on a mapping solution which is in the realm of Advanced Driving Assistance System for smart cruise control, for commercial vehicles. For our European customer, we map gradient of the road (altitude change per horizontal distance travelled on road) and curvature of a road or across a junction. These features assist the driver in reducing the speed of the vehicle at the curvature and optimise the flow of the fuel during the altitude change. A lot of accidents take place at cloverleaf intersections and a lot of fuel is burnt when the driver sees upward gradient. Our mapping solution assists drivers to solve these issues. This is now being used extensively with trucks all over Europe.

We have also developed a concept of ‘Digital Twins’ for cities across Europe, where we work with our partners, to provide a digital replica of the city, using all the data that has been collected with regard to roads, power distribution systems, street lights, water distribution, sewage collection and stormwater drains. This tool helps city governments to easily plan and execute projects and also to simulate various kinds of disaster scenarios and understand how various systems and subsystems would work under stress. It is useful for simulating scenarios like urban floods, or severe traffic jams. Twenty European cities use this solution, and it has been working for the past six years.

Venkatesh Kannaiah: What are your innovations in the field of precision agriculture and waste management?

BVR Mohan Reddy: We are not into precision agriculture per se but with a solution that is unique. We have worked with drones in agriculture and have a great understanding on collecting large quantities of data using Lidar equipment mounted on drones and then do image processing to understand several parameters such as health of crop, yield, duration to harvesting, water usage, and around soil. We could collect data on 64 parameters related to a single farm for interventions and actions thereafter.

We are using this expertise to work with partners in Europe and have built a platform for managing subsidy provided to EU farmers. Our platform manages a variety of factors, from subsidies given by multiple agencies to subsidies based on flooding or crop quality or even subsidies when high density power lines run over farms. We use satellite and drone imagery to interpret the farm data with a variety of AI tools.

We also work on carbon capture and storage with the city of Oslo. We work on capturing emissions from waste to energy plants which emit about 17 per cent of the city’s emissions.

Venkatesh Kannaiah: Can you name some products /themes that you have been working on, that have an immediate relevance to India and which India can adopt — all with reference to social impact?

BVR Mohan Reddy: Most of the projects that we work with internationally are with partners. Some of them are very relevant to India.

For example, the concept of a ‘Digital Twin’ for Indian cities is very relevant. We need to build such ‘Digital Twins’ to simulate and solve problems. However, we must understand that such digital solutions require a large amount of data to be collected to be effective and relevant. In India, we need to do technology upgradation,such as use of sensors for collecting large amounts of data, and digitising the cities’ networks which will lead to effective decision making based on data and evidence.

The idea of land mapping is also something very relevant to India. However, there are a lot more challenges in India, apart from paucity of data. After all, issues of land and property are enmeshed in a lot of legacy systems, and it is difficult to unbundle them.

Venkatesh Kannaiah: Can you talk about your interventions in the Indian innovation ecosystem like the Global innovation hackathon and BVR Mohan Reddy school of Innovation?

BVR Mohan Reddy: As for the Global Innovation hackathon, we frame the challenges and it is centered around the themes of sustainability, mobility and the circular economy. We have held such events with local partners too.

One with the LV Prasad Eye Institute gave birth to interesting innovations. A startup came up with an idea of tracking the eye movements of an infant with novel baby incubators which helped to detect optometry issues very early on. The challenge was that it was difficult to examine the eyes of a newborn. These novel incubators had lights and sensors which picked up the data from the eyes whenever they reacted to light sources and analysed the data with ease.

The second one was an affordable tool to check eyesight of children. Now, a large number of govt schools in Telangana have this tool and helps identify visual challenges at an early age.

We have also given a grant of Rs 20 crore to BVR Mohan Reddy School of Innovation and Entrepreneurship (BVR SCIENT) which in collaboration with IIT Hyderabad aims to develop innovation and entrepreneurial ecosystem.

Venkatesh Kannaiah: What is going right and what’s going wrong with the innovation ecosystem in India, with particular reference to engineering education?

BVR Mohan Reddy: This is a great time for entrepreneurship in India, and we must move away from rote learning and build a failure-friendly system. Unless we are willing to take risks, and sometimes fail, we cannot improve. Design thinking, critical thinking, challenging status quo, patience and persistence are the key. A focus on knowledge, research and commercialisation of innovation should be embedded into our education system.

Venkatesh Kannaiah: What do you think are the gaps in the funding of the innovation ecosystem in India?

BVR Mohan Reddy: There is not enough focus on deep tech or disruptive tech in our curriculum. Most of the innovation is copycat, and there is not much of a focus on really innovative solutions. Atal Innovation Labs and Atal Tinkering Labs are doing their bit to provide new ideas at the school and college level, but a lot needs to be done.

Venkatesh Kannaiah: Are we ready in terms of tech and manpower to reimagine supply chains away from China and make in India?

BVR Mohan Reddy: My reading of the situation is that western companies are looking at a China plus one model, i.e., another manufacturing destination in addition to China to de-risk themselves. There also could be some companies willing to completely move away from China.

Supply chain ecosystems are hard to build. There is the issue of skill upgradation, ease of doing business, the cost of doing business, seamless logistics and the ability of the system to absorb new and innovative tech. A larger, hardworking, passionate and nimble-footed skilled workforce is needed to absorb new tech.

It requires a long term plan and strategy, and I assume that it is being set in place. It is easier said than done.

Venkatesh Kannaiah: Have there been any impact investments at Saranam Ventures, your personal venture vehicle?

BVR Mohan Reddy: We have invested in a few social impact startups. One of these is Cardiac Design Labs (CDL) and one of their products aims to maintain the Holter’s high quality ECG outputs through leveraging the benefits of a patch. It monitors heart condition and provides the information to the cloud, and your doctor can monitor the same online. Earlier devices were not connected to the cloud and had to be given to the doctor manually at periodic intervals. The solution also alleviates the burden on clinical staff, allowing them to focus on patient care. The remote monitoring services also allow continuous monitoring of patient data in any environment.