IISc team builds indigenous ventilator prototype for COVID-19 patients

The ventilator is made completely using components found or made in India and is expected to be ready within the next couple of weeks. Several researchers had pointed out that India may face a shortage of ventilators in the coming days, much like other countries across the globe.

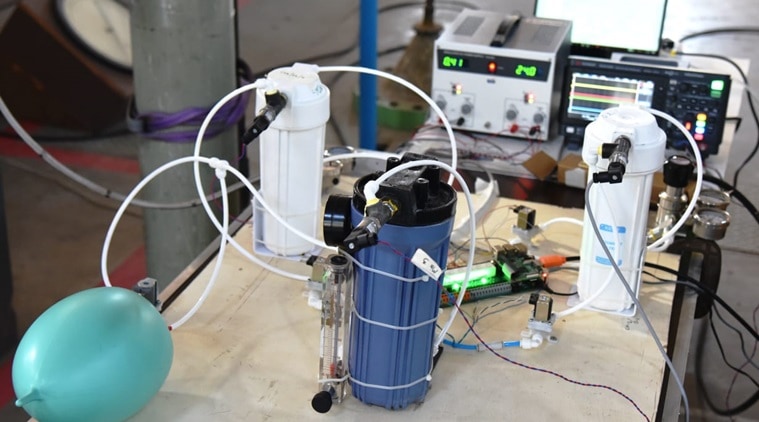

The team is also getting inputs from doctors to simplify the interface and create a dashboard preloaded with approved settings. (Photo/IISc)

The team is also getting inputs from doctors to simplify the interface and create a dashboard preloaded with approved settings. (Photo/IISc)

In a bid to address the shortage of ventilators to fight the COVID-19 pandemic, a team of engineers at the Indian Institute of Science (IISc) is currently building a prototype of an electro-mechanical ventilator from scratch — based on guidelines issued by the UK Medicines and Healthcare products Regulatory Agency.

According to an IISc statement, the ventilator is made completely using components found or made in India and is expected to be ready within the next couple of weeks. “We are building it so that anyone can use it free of cost,” T V Prabhakar, Principal Research Scientist at the Department of Electronic Systems Engineering (DESE) and one of the founders of the project stated.

Read| The business of breathing: What does it take to build a ventilator, who can do it?

Several researchers had pointed out that India may face a shortage of ventilators in the coming days, much like other countries across the globe.

Some of the key challenges faced by manufacturers include sourcing of key components like sensors and flow controllers from overseas as global supply chain disruption continues due to the pandemic.

Explaining the progress of the project, Gaurab Banerjee, Associate Professor at the Department of Electrical Communication Engineering and one of the project coordinators, added that the team has been for the last 10 days to ensure this technology gets going.

“We hope that by the end of April, manufacturers can have their own prototypes done, which they can scale up very quickly,” Banerjee said.

Read| IITs join COVID-19 fight, offer low-cost ventilators, test kits

According to the team, about 40,000 ventilators are available across the country at present. However, if the number of severe cases of COVID-19 increases, thousands of more ventilators may be required and will have to be produced very quickly.

“Patients with severe COVID-19 infection have inflamed or damaged lungs that struggle to receive sufficient oxygen. When doctors put them on a ventilator, the machine critically assists lung function, feeding the patients a controlled mixture of air and oxygen and buying their body time to fight the infection,” the IISc statement mentioned.

According to Pratikash Panda, Assistant Professor at the Department of Aerospace Engineering, a member of the team, not many ventilator components is manufactured in India.

The team has, therefore, built some components while others are co-opted.

“The mixing process that we have come up with has parallels to those in gas turbines and industrial burners, where the ratio of fuel and oxidizer is carefully controlled,” Panda said.

According to the Institute, the team is also getting inputs from doctors to simplify the interface and to create a dashboard preloaded with approved settings. This would allow it to be operated quickly in an emergency even by untrained technicians or nurses.

“They would just have to press a button that says pneumonia or Acute Respiratory Distress Syndrome (ARDS), and all the settings will come up by default within a certain range,” Banerjee added.

Another team member, Duvvuri Subrahmanyam, Assistant Professor at the Department of Aerospace Engineering, said the team is using sensors similar to those used to detect air pressure in car tyres.

- 01

- 02

- 03

- 04

- 05